In today’s competitive business landscape, maximizing productivity is crucial for success. One way to increase efficiency and productivity is by investing in advanced die cutting technology.

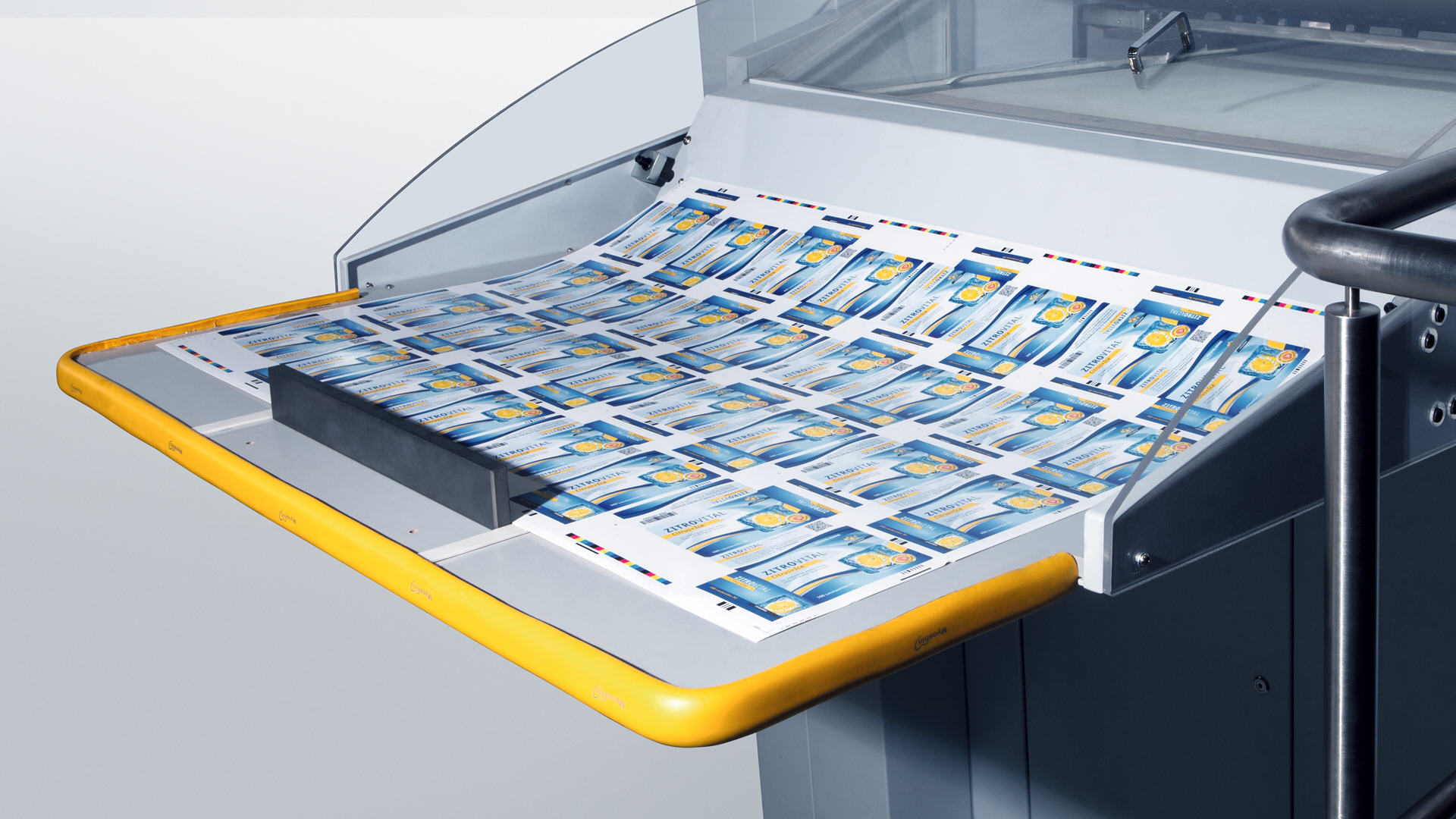

Die cutting is a manufacturing process that involves the use of specialized machinery to cut, shape, or form materials into specific designs or shapes. With the right die cutting technology, you can significantly improve your production processes and take your business to the next level.

One type of advanced die cutting technology is digital die cutting. Digital Die Cutting Machinery, also known as laser or waterjet cutters, use computer-controlled lasers or high-pressure water jets to cut materials with precision. These machines are ideal for small, intricate cuts and can handle a wide range of materials, including paper, cardboard, plastic, and more.

One of the primary benefits of digital die cutting technology is the ability to quickly and easily make design changes. With traditional die cutting methods, making changes to a design often requires the creation of a new physical die, which can be time-consuming and costly. With digital die cutting, changes can be made quickly and easily through computer software, saving time and money.

Another benefit of digital die cutting is the ability to customize products on-demand. With traditional die cutting methods, large quantities of a single product must be produced, leading to excess inventory and potential waste. Digital die cutting allows for the production of small batches or even single items, reducing waste and increasing efficiency.

In addition to digital die cutting, there are also other types of advanced die cutting technology on the market, including computer-controlled flatbed and rotary die cutting machines. These machines use advanced software and automation to increase accuracy and efficiency in the die cutting process.

Investing in advanced die cutting technology can also improve the quality of your products. With the use of computer-controlled machinery, you can achieve precise cuts and finishes, resulting in a higher-quality end product.

To get the most out of your advanced die cutting technology, it is essential to properly train operators on the use of the equipment and ensure that it is properly maintained. Regular cleaning and lubrication, as well as the replacement of worn or damaged parts, will help ensure optimal performance.

In conclusion, advanced die cutting technology can significantly improve productivity and efficiency in your business. Whether you choose digital die cutting or computer-controlled flatbed or rotary die cutting machines, investing in the right technology can help take your business to the next level.